If you would like to learn more about Springpack and our services, use the form below to submit an enquiry, or get in touch with one of our packaging experts by…

How to save on packaging costs

How to Save on Packaging Costs

The most effective way to reduce your overall packaging spend is to swap to more efficient solutions. Often, a small change in specification can deliver big savings. This could be savings in labour, materials, or improved operational efficiency – most of the time it’s all three.

Let’s take a look at some quick swaps you could make to save on packaging costs – without cutting corners.

48mm Tape vs 72mm Tape

Save Up to 50% on Tape Usage

It’s pretty common to be sealing a box with two, or even three lengths of 50mm tape. If this is your method, why not make a simple switch over to 75mm tape? It can significantly reduce the amount of tape you are using per box.

Up to 50% reduction in tape usage

Faster carton sealing

Fewer roll changes

Immediate material and labour savings, with no compromise on packaging effectiveness.

66m Tape vs 150m Tape

If you're changing over 40 rolls of tape a day, that's an hour of tape-changing time.

Cheaper upfront costs are costing you more than you think. Shorter tape rolls may seem cheaper, but they cost more in lost productivity. It takes around 90 seconds to change a tape roll.

Real improvements you can expect to see when swapping to longer rolls

Fewer interruptions to packing lines

Improved packing efficiency

Less storage is required for tape

Hand Wrap vs Machine Wrap

Reduce film usage, boost wrap tension.

Wrapping more than 25 pallets per day? A pallet wrapping machine could save you time and money. Compared to hand wrapping, machines:

Use less film

Deliver consistent, secure loads

Increase wrapping speed and throughput

Free up operatives for other tasks

Hand Wrap vs Aero Dispenser

Smarter Manual Wrapping

Experiencing bottlenecks at peak times?

Perhaps you don’t need another pallet wrap machine yet, but there are times you need a few extra pallets wrapped. Or maybe, you just don’t fancy dipping a toe into packaging automation just yet. We understand they’re not the right fit for everybody!

If a wrapping machine isn’t right for your operation yet, an aero dispenser is a game-changing upgrade from standard hand wrapping. Aero dispensers:

Apply film at a consistent tension

Reduce film waste

Improve operator comfort and reduce physical strain

Aero dispensers are perfect portable product packaging solutions – try saying that one a few times.

Investing in equipment that can make your packaging process smoother often outweighs the initial outlay of the packaging equipment.

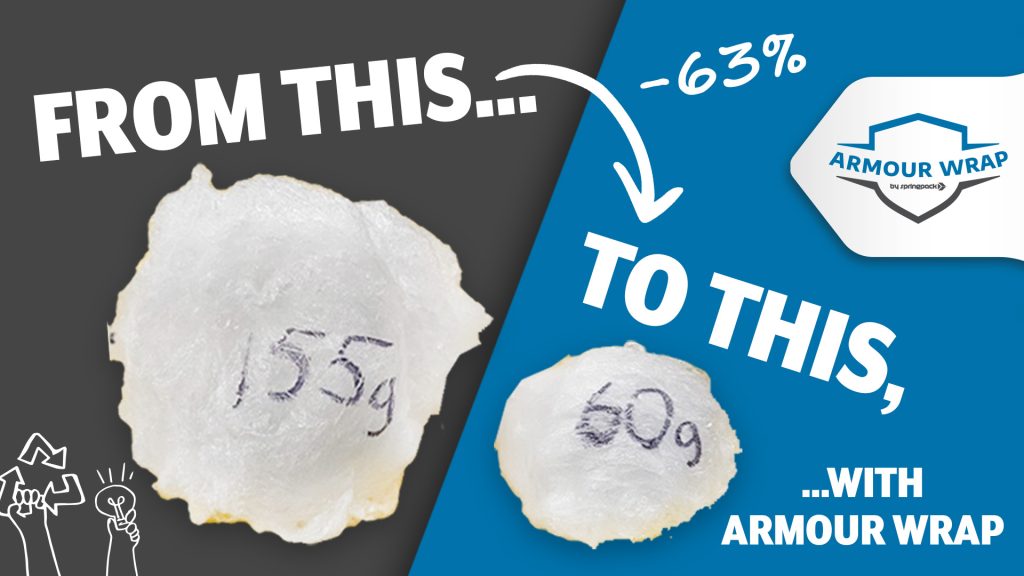

250% Stretch vs 350% Stretch Machine Wrap

Extra stretch to your machine film is another great way to reduce costs for transit packaging.

Using a standard machine film thicker than 17mu? You could be wrapping more pallets with less film.

Swapping to high-performance film like Armour Wrap that offers up to 350% stretch allows for more pallets to be wrapped per roll, better load stability, and less waste in the supply chain.

Key advantages of Armour Wrap:

Up to 50% reduction in film costs

Stronger, lighter film

Improved pallet stability

Higher stretch means fewer wraps, less film, and lower spend per pallet.

Manual Strapping vs Friction Weld Tools & Auto Strapping Machines

Manual strapping is slow, tiring, and uses consumables. Switching to friction weld tools or automatic strapping machines means you need no additional materials; they seal the strapping to itself.

Strap products with no seals needed

Reduce operator fatigue

Improve strap consistency and security

The result is faster throughput and lower costs per unit.

Paper Shooter vs Manual Void Fill

Manually filling void space is time-consuming and inconsistent. A paper shooter speeds up the process.

Benefits include:

Faster packing times

More consistent void fill

Reduced material waste

It’s an easy way to improve packing efficiency while maintaining excellent product protection.

Buy Bespoke Packaging in Bulk

You can save with Smart Stock Holding

Ordering bespoke packaging in bulk unlocks valuable price breaks, but warehouse space can be a concern. Springpack solves this with stock holding and just-in-time deliveries, allowing you to:

Benefit from bulk pricing

Avoid tying up warehouse space

Maintain a consistent supply

You get the best of both worlds: lower unit costs and flexible deliveries.

Small Packaging Changes, Big Cost Savings

Reducing packaging costs doesn’t require cutting corners; instead, it requires making smarter choices. By swapping to more efficient tapes, films, machines, and systems, businesses can dramatically reduce material usage, save time, and lower labour costs.

At Springpack, we specialise in helping customers find packaging solutions that deliver better performance for less spend. Whether it’s a simple product upgrade or a complete packaging review, small changes can unlock big savings across your operation.

If you are interested in Packaging, Springpack are experts in the field. Our team of Packaging Experts have all of the answers to your packaging questions. Why not get in touch with us today?